From Centrifugal Compressors to Radial Turbines: How the TurboTides Intelligent Collaboration Platform Solves the Triangular Dilemma in Turbomachinery Design

The Bottlenecks in Traditional Turbomachinery Design and TurboTides’ Breakthrough

Traditional turbomachinery design often presents challenges,

including low efficiency, high costs, and difficulties in innovation.

Designers have to spend a significant amount of time and effort on tedious

manual calculations and repeated trial-and-error verifications, yet they still

struggle to achieve optimal design results.

This process is akin to navigating through a thicket—every step is filled with

obstacles. However, TurboTides emerges like a guiding light,

illuminating the path forward.

Comparison of Traditional vs. TurboTides Design

|

Comparison Dimension |

Traditional Design |

TurboTides Design |

|

Design Process |

Disjointed tools and steps; cumbersome data transmission |

Integrated platform covering the entire process from thermodynamic cycle analysis to multidisciplinary optimization |

|

Design Efficiency |

Manual operations and data transfer; low efficiency with high risk of data loss |

Automated data transmission and lossless model transfer to enhance efficiency |

|

Design Accuracy |

Dependent on experience and basic calculations, resulting in limited precision |

Advanced simulation analysis and data calibration for high precision |

|

Collaborative Design |

Isolated information between design stages; difficult team collaboration |

Embedded database supporting networked design management for seamless teamwork |

|

Optimization |

Optimization is difficult and relies mainly on designers' experience |

Built-in multidisciplinary optimizer for rapid optimal solution searching and improved design quality |

|

Technical Support |

General software support teams that respond slowly to industry-specific problems |

Expert team specializing in turbomachinery, offering targeted support |

TurboTides:

A Pioneer in Turbomachinery Design

TurboTides is more than just a tool—it represents a new

design philosophy. It simplifies the complex design process into a few

key steps, enabling designers to complete their work with greater speed and

accuracy.

Whether it's centrifugal compressors, radial turbines, or other intricate

mechanical components, TurboTides effortlessly handles the task, serving as

a powerful digital design assistant.

Intelligent Optimization: Unlocking Hidden Potential

The intelligent optimization feature in TurboTides functions

like an experienced mentor, guiding designers toward the best design

solutions.

By analyzing and processing large volumes of data, it quickly evaluates the

performance of different design options and selects the optimal

combination.

This not only enhances design efficiency but also sparks innovative

thinking, allowing designers to break free from traditional design

limitations and explore more novel and effective solutions.

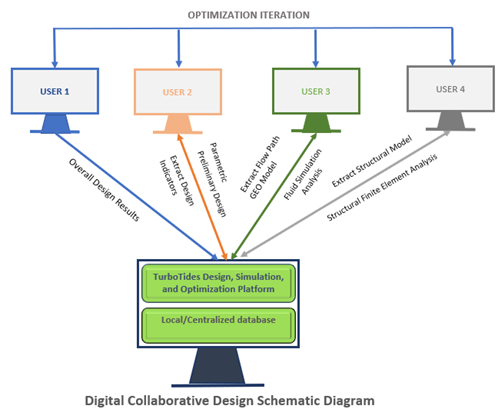

Digital Collaboration: Breaking the Information Silos in

Design

In modern turbomachinery design, team collaboration is

crucial. TurboTides’ digital collaboration feature eliminates the information

silos found in traditional design methods.

It allows designers from different departments and disciplines to

communicate and collaborate efficiently on a unified platform.

Design data can be shared and managed effortlessly, significantly boosting

overall team productivity and innovation.

The Future is Here: TurboTides Leading the New Wave of

Turbomachinery Design

By integrating AI, big data, and cloud computing with

turbomachinery design, TurboTides provides designers with an intelligent,

efficient, and collaborative design environment.

In this ecosystem, designers can embrace new challenges with an open mind

and innovative approach, creating groundbreaking industrial designs.

In this era full of opportunities and challenges, TurboTides is undoubtedly the most trusted partner for turbomachinery designers, empowering them to move forward on their design journey and write their own remarkable success stories.

Please contact us if you have any questions or would like to schedule a live demonstration.